- Summary

- Applications

Valve is an indispensable flow control device in national economic fields like petrol chemical, power generation, pipelines, shipbuilding . The valve is used to stop, throttle, change pressure or flow of the medium in the pipelines. Valves used in industrial and civil engineering are generally: gate, globe, check, ball, butterfly, throttle, safety and relieve valves.

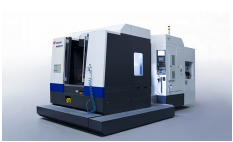

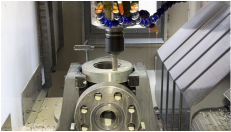

Based on 20 some yea rs of experience in valves and petrol equipment, Neway is able to offer CNC machines with better cutting performance. High torque and rigidity are the main requirements of valve and petrol equipment. With facing plate installed on Neway horizontal machine center, complicated cutting process is possible. Neway developed efficient gantry drilling center to enable efficient working process of large size valves. Stable CNC equipment assures you with better opportunities, shorter working time and lower cost.

Major related productsMore>

Major related productsMore> Typical Machining Parts

Typical Machining Parts

7835143.jpg)

-

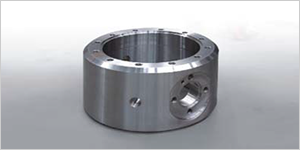

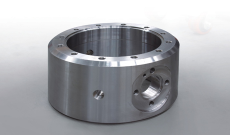

Valve Body

Valve Body

Characteristics:

Ball valve body 6" 600lb,3-pc fixed ball valve

Material:LF2

Process: turning①milling and drilling①milling and drilling②

machining allowance:2MM(single side)

cycle: 31min

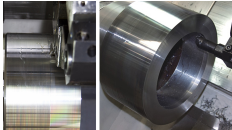

turning process①

Model recommended:

NL502SC lathe

exchangeable general fixture and tool, highly efficient Hydro 3 jaw chuck, turning the other end, OD,ID and end face

Tools selection:

T01:circular cutting tool DCLNR25252M12+blade CNMG120408-PR422515

T02:circular cutting tool DCLNR25252M12+blade CNMG120408-PR4215

T03:bore boring tool A40T-DCLNR12+blade CNMG120408-PR4225

T04:bore boring tool A40T-DCLNR12+blade CNMG120408-PR4215

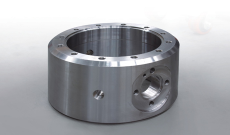

Characteristics:

Ball valve body 6" 600lb,3-pc fixed ball valve

Material:LF2

Process: turning①milling and drilling①milling and drilling②

machining allowance:2MM(single side)

cycle: 31min

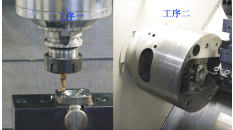

Milling and drilling process②

Model recommended:

VM503D Horizontal Milling Center

Hydro 3 jaw chuck, clamp on OD, drill flange holes;

Tool selection:

T01:rotary blade driller 880-1950L25-03

T02:bevel driller E6819TIN-31

T03:taper screw tap 2256-UNC7/8

cycle:6MIN

Characteristics:

Ball valve body 6" 600lb,3-pc fixed ball valve

Material:LF2

Process: turning①milling and drilling①milling and drilling②

machining allowance:2MM(single side)

cycle: 31min

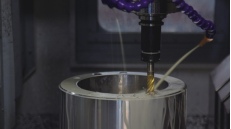

Milling and drilling process②

Model recommended:VM503D

Horizontal Milling Center

One mount for multiple process, face plate for option;

process description:position by bore, make side holes with help of fixture;

Tool selection:

T01:rotary blade driller 80-D4000L40-03

T02:face plate: R390-063Q22-11M

T04:ф12 driller

T05:ф8 driller

T06:rotary blade driller 880-D2300L25-03

T07:bevel driller:E6819TIN-31

T08:M14 crew tap:205675-M14

T09: 3/4-14NPT screw tap 25167-NPT3/4

cycle:15MIN

-

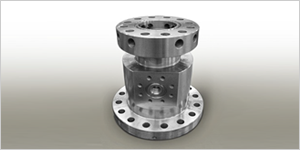

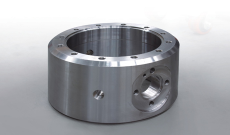

Forged Valve Body

Forged Valve BodyForged Valve Body

Introduction:

Part Name: 3/4" forged valve body

Material:ASTM A105N

Work allowance:3mm single side,solid

Model recommended:

FMS-001 Automatic production

line NL502SC+VM903H

Basic requirement:

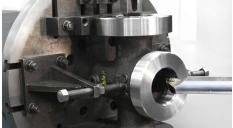

Process① NL502SC lathe

Process②VM903H Vertical milling center

Process①

Model recommened:VM903H

Description: 4 axis, hydro fixture, positioning by outside, processing 3 sides

cycle:4min

process②

model recommended:NL502SC process description:use collect chuck to process 3 sides

cycle: 4min

-

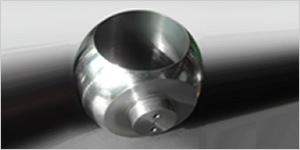

Part Introduction:

Part name:2-1/16’API6A Gate valve body

Material:ASTM A487 4C

Process:turning process① turning

process② drilling process

Work allowance: 4MM

Cycle:30min

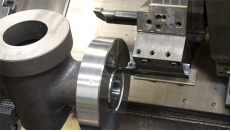

Turning process①

Model recommended:NL634SZ lathe

use exchangeable general fixture for easier mounting

Description: on fixure, turn both ends on flanges;

Tool selection:

T01:circular cutting tool DCLNR2525M12+blade CNMG120408-PR4215

T02:end face tool RF123H13-2525B-132BM+blade N123H2-0400-TM4255

T03:boring tool A50U-DCLNL16+blade CNMG160608-PM4225

T04:special boring tool (for port bore and seat hole)

Part Introduction:

Part name:2-1/16’API6A Gate valve body

Material:ASTM A487 4C

Process:turning process① turning process② drilling process

Work allowance: 4MM

Cycle:30min

turning process②

model recommended:NL634SZ lathe

Use exchangeable fixture to clamp valve by flange ends, turn the opening in the middle;

Tools:

T01:excircle cutting tool DCLNR2525M2 + blade CNMG120408-PR4215

T02:boring tool A50U-DCNLR16+blade CNMG160608-PM4225

cycle:10MIN

Characteristics:

Part name:2-1/16’API6A Gate valve body

Material:ASTM A487 4C

Process:turning process① turning process② drilling process

Work allowance: 4MM

Cycle:30min

drilling process

Vmodel recommended:VM905T

Vertical Milling Center

Characteristics:use special fixture to hold parts securely;

Description:clamp by flange ends, make holes on flanges and opening in the middle, thread screw as well;

tools selected:

T01:rotary tip driller 880-D3200L40-03

T02:bevel driller

T03:thread screw

cycle:25MIN

Return

Return