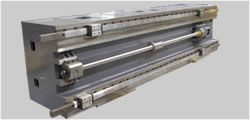

PM Series HB Portal Machining Center

- Product Overview

- Product features

- Technical Parameters

HB series

|  | |

01、Integral structure Large size components are of resin sand cast iron with high tensile strength, finite element analyzed, rigid and able to perform high torque cut. | 02、machine bed guide rail Imported roller linear guide rail, PM20H and smaller size machines are designed with bi-rails, PM25H and above with a quadriad of rails. The machine is strong with good dynamic performance and long rail life span. | |

|  | |

03、beam guide rail Heavy duty linear guide rail with nice dynamic cutting performance, creepless at low speed. | 04、spindle box 450 x 500mm T ram with belt drive, stable processing performance. The carrier is lubrication strengthened with inlay plastic. | |

Portal frame structure, traveling worktable (X axis), spindle box traveling (Z axis), saddle traveling on the beam (Y axis), square ram design and twice speed reducing with retarders offer low speed constant torque and high speed constant power cutting. High speed, acuracy, agility, To be used for ferrous and nonferrous metal process. Recommend for civil aviation, vehicle, resource, IT and pattern industries.

| Item | Unit | PM1620HB | PM1630HB | PM1640HB |

| Woktable Size | mm | 1600 x 2000 | 1600 x 3000 | 1600 x 4000 |

| Max loading capacity | kg | 8000 | 10000 | 12000 |

| Woktable travel (X axis) | mm | 2200 | 3200 | 4200 |

| Ram travel (Y axis) | mm | 2100 | 2100 | 2100 |

| Spindle box travel (Z axis) | mm | 1000 | 1000 | 1000 |

| Spindle face to worktable | mm | 200 ~1200 | 200 ~1200 | 200 ~1200 |

| Distance between two columns | mm | 2200 | 2200 | 2200 |

| Spindle taper | BT50 | BT50 | BT50 | |

| Spindle speed | r/min. | 40 ~ 6000 | 40 ~ 6000 | 40 ~ 6000 |

| Max torque | N.m | 525/647 | 525/647 | 525/647 |

| Spindle motor power | kw | 15/18.5 | 15/18.5 | 15/18.5 |

| Ram section | mm | 400 x 400 | 400 x 400 | 400 x 400 |

| X / Y / Z axis rapid speed | m/min. | 12/15/15 | 12/15/15 | 12/15/15 |

| Automatic Tool Change Standard (ATC ARM TYPE) | pc | 24 tools | ||

| Max tool diameter/lenght/weight | mm/mm/kg | 105/350/15 | 105/350/15 | 105/350/15 |

| Max tool diameter (empty neighbor cell) | mm | 200 | 200 | 200 |

| Positioning accuracy (X/Y/Z) | mm | 0.016/0.016/0.016 | 0.020/0.016/0.016 | 0.025/0.016/0.016 |

| Repositioning accuracy (X/Y/Z) | mm | 0.010/0.010/0.010 | 0.012/0.010/0.010 | 0.016/0.010/0.010 |

| Lubrication oil cooling system and cutting coolant | Standard | |||

| CNC system | NEWAY FANUC / SIEMENS | |||

| Machine weight | kg | 28000 | 30000 | 35000 |