Present location:

Home ProductDouble Column Machining CenterPM series - Movable column gantry machining center

PM series - Movable column gantry machining center

- Product Overview

- Product features

- Technical Parameters

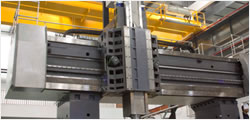

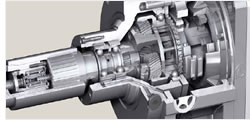

| Fixed worktable, portal frame traveling (X axis), spindle box traveling (Z axis), saddle traveling on the beam (Y axis), square ram design and twice speed reducing with retarders offer low speed constant torque and high speed constant power cutting. High speed, acuracy, agility, heavy load. Fixed worktable for heavy workpiece process. Beams move upwards and downwards for workpiece with extreme height. |

| tyre pattern > MORE |  | cylinder > MORE |

| fixture > MORE |  | plane parts件 > MORE |

|  | |

01、beam structure Integral design, wide work range, efficient, precise feeding in. | 02、Y axis Gear and rack transmission, driven with two motors . | |

|  | |

03、speed reducing ZF retarder and Neway gearbox increase output torque for heavy duty cut. | 04、high torque spindle Taiwan heavy load spindle produces high torque for heavy duty cut. | |

Item | Unit | PM30100MHZ | PM30120MHZ | PM30140MHZ | PM30160MHZ | PM30120MSC | PM30140MSC | PM30160MSC | PM40100MSC | PM40120MSC | PM40140MSC | PM40160MSC |

Worktable width | mm | 3000 | 3000 | 4000 | ||||||||

Worktable length | mm | 10000 | 12000 | 14000 | 16000 | 12000 | 14000 | 16000 | 10000 | 12000 | 14000 | 16000 |

Worktable travel(X axis) | mm | 1050+750 (change head) | 12500+750 (change head) | 14500+750 (change head) | 16500+750 (change head) | 1050+750 (change head) | 14500+750 (change head) | 16500+750 (change head) | 1050+750 (change head) | 12500+750 (change head) | 14500+750 (change head) | 16500+750 (change head) |

Carriage travel(Y axis) | mm | 4600 | 4600 | 5200[5600] | ||||||||

Ram travel (Z axis) | mm | 1250[1500] | 1250[1500] | 1500 | ||||||||

Column span | mm | 4200[4600] | 4200[4600] | 500-2000 | ||||||||

Spindle speed | r/min | 40~3500 | 40~2500 | 40-2500 | ||||||||

Max.output torque | N.m | 1120/1320 | 1993/2458 | 1993/2458 | ||||||||

Spindle motor power | kW | 22/26 | 30/37 | 30/37 | ||||||||