Automatic Box Processing Line

The project is composed of dozens of horizontal machining centers, which cooperate with the automatic loading and unloading of truss manipulator. The machine tool works 300 days a year and is produced in three shifts, 21.3 hours a day, with an annual output of 200000 pieces. The beat of the production line is ≤ 96 seconds / piece (including all auxiliary time such as loading and unloading time of manipulator 25 seconds, probe replacement time and detection time). The part processing content CMK ≥ 1.67

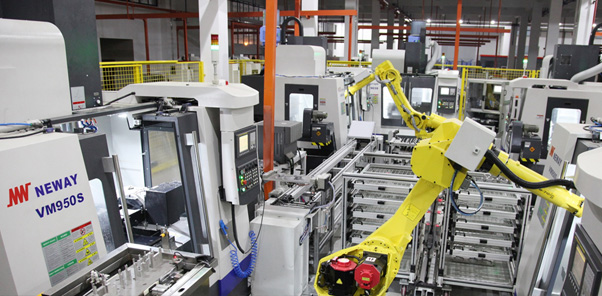

Automatic Oil Circuit Valve Processing Line

The automatic line is composed of two hm50td horizontal machining centers and one vm1160h vertical machining center. Combined with joint robot + ground rail automatic line, it can meet the processing of 22 kinds of valve bodies and has expansibility. The production line is connected with MES information system to realize data sharing in the process of valve body processing, and realize the full automation of production processes such as material identification, loading, clamping, turnover, processing and blanking. The processing efficiency of the valve body is increased by more than 50%, and the manufacturing cost is reduced by 18%.

Automatic Flywheel Housing Machining Line

The automatic line consists of two vertical machining centers, one horizontal machining center and joint robot to realize the automatic clamping and machining of workpieces, reduce the machining process, reduce the staffing and labor intensity, and improve the machining efficiency and stability. Customers purchase dozens of vertical machining centers and horizontal machining centers to form more than ten production units, which greatly saves manpower and realizes efficient processing.

Automatic Box Cover Parts Processing Line

There are two automatic lines in the project, one line processes three types of boxes of gasoline saws and one line processes two types of boxes of irrigation mowers. The automatic line is equipped with visual recognition during the processing from blank to finished product, which realizes three types of boxes of gasoline saw and two types of boxes of irrigation mower. During automatic processing, various models can be switched freely; The automatic line is equipped with an automatic detection system. In the whole operation process of the automatic line, there is no need to detect the size manually. At the same time, it is equipped with intelligent SPC display, which can display the processed products, quantity, product size, qualification rate and data analysis. One person is on duty, and an automatic processing production line composed of 13 machine tools is realized.

Compound Machining Automatic Line

The automatic line is composed of two nl201hg and two nl201h CNC horizontal lathes, three vm903sl vertical machining centers, five sets of truss manipulators and six sets of buffer material channels. The truss length is 36.5m, the processing beat of the whole line is 27 seconds, and the annual output reaches 800000 pieces. Adopt manipulator for refueling to reduce staffing and labor intensity; Improve processing stability, increase output and reduce cost.

Claw Pole Processing Automatic Line

The automatic claw pole processing line is composed of two nl201hc horizontal CNC lathes, truss manipulator, rotating silo, turnover station, manual sampling station and other equipment to realize the automatic claw pole processing. The beat of the whole line is 46 seconds / piece, with an annual output of about 500000 pieces.

End!!